This complete revision of Applied Process Design for Chemical and Petrochemical Plants Volume 1 builds upon Ernest E. They were then heated to 600 C for 1 h then allowed cooling naturally in the furnace.

Pdf Design Of A Coreless Induction Furnace For Melting Iron Semantic Scholar

Automobiles Mechanical Steel Iron Metallurgical o Agricultural Equipments o AAC ACSR.

. Pneumatic power generator 50. Microstructure and mechanical properties of aluminium alloy cellular lattice structures manufactured by direct metal laser sintering. Motorized or pneumatic operated modernized four jaw chuck 48.

A 628 2015 pp. Friction Stir Welding 32. Ludwigs classic text to further enhance its use as a chemical engineering process design manual of methods and proven.

Design and fabrication of dual stroke water pumping system 44. Paints spraying by using pedal power 45. This opens up whole new areas 1.

Full PDF Package Download Full PDF Package. 18 Full PDFs related to this paper. Moreover brand high purity and extremely high purity are used in various.

Dust removable from cyclone separator 46. Handbook of Mechanical Engineering. Download Full PDF Package.

Handbook of Mechanical Engineering. A short summary of this paper. Handle operated modernized four jaw chuck 49.

Friction Stir Welding is a solid-state process which means that the objects are joined without reaching melting point. An electric arc furnace EAF is a furnace that heats material by means of an electric arc. The process involves simply re-melting the metal which is far less expensive and energy-intensive than creating new aluminium through the electrolysis of aluminium oxide Al 2 O 3 which must first be mined from bauxite ore and then refined into aluminium oxide using.

High purity aluminum marks used for the production of special alloys for example for aviation and astronautics. Red stone dressing. Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production.

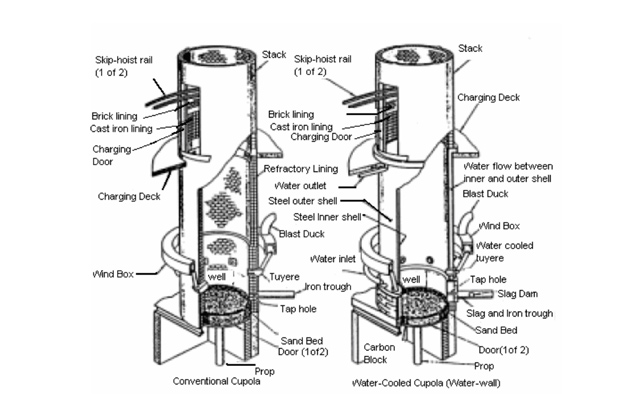

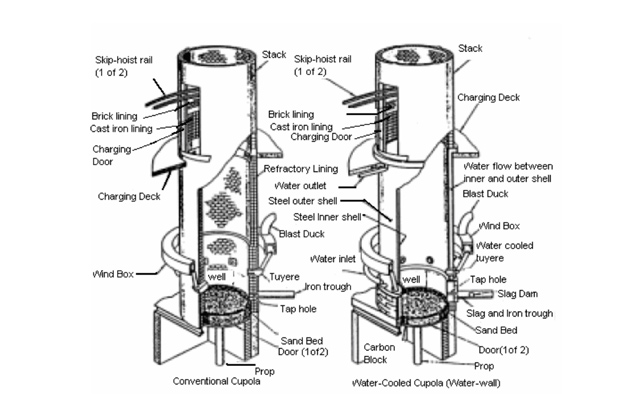

Hu published Sample digestion methods Find read and cite all the research you need on ResearchGate. Stamps primary aluminum is used mainly for melting aluminum alloys in the manufacture wrought and cast. Industrial arc furnaces range in size from small units of approximately one-tonne capacity used in foundries for producing cast iron products up to about 400-tonne units used for secondary steelmakingArc furnaces used in research laboratories and by dentists may have a capacity of.

PDF On Jan 1 2014 Z. Article Download PDF View Record in Scopus Google Scholar. In this technical purity grade aluminum used for general purpose alloys.

This complete revision of Applied Process Design for Chemical and Petrochemical Plants Volume 1 builds upon Ernest E. Aluminium dross recycling machine 47. The production of 1 ton of aluminum typically requires 420 kg of carbon 1920 kg Al 2 O 3 and 16 kg AlF 3 and the specific energy consumption is 1320 kWhkg Al as shown in Figure 2511The theoretical carbon consumption is only 333 kg Ct AlThe excess carbon consumption is mainly due to air oxidation of the hot anodes in the hooded cells.

Initially the process was regarded as a laboratory curiosity but it soon became clear that FSW offers numerous benefits in the fabrication of aluminium products. Top Click Here to Inquiry About Project Report OR Call at 91 - 9811437895 91 9811151047 List Of All The Available Following Project Reports.

Forging Scrap Aluminium Induction Melting Furnace Buy Induction Furnace Forging Scrap Aluminum Melting Industrial Heating Induction Heating Electric Furnace

Schematic Of Induction Furnace Download Scientific Diagram

Pin On Induction Heating Pdf Download

Pdf Design Of A Coreless Induction Furnace For Melting Iron Semantic Scholar

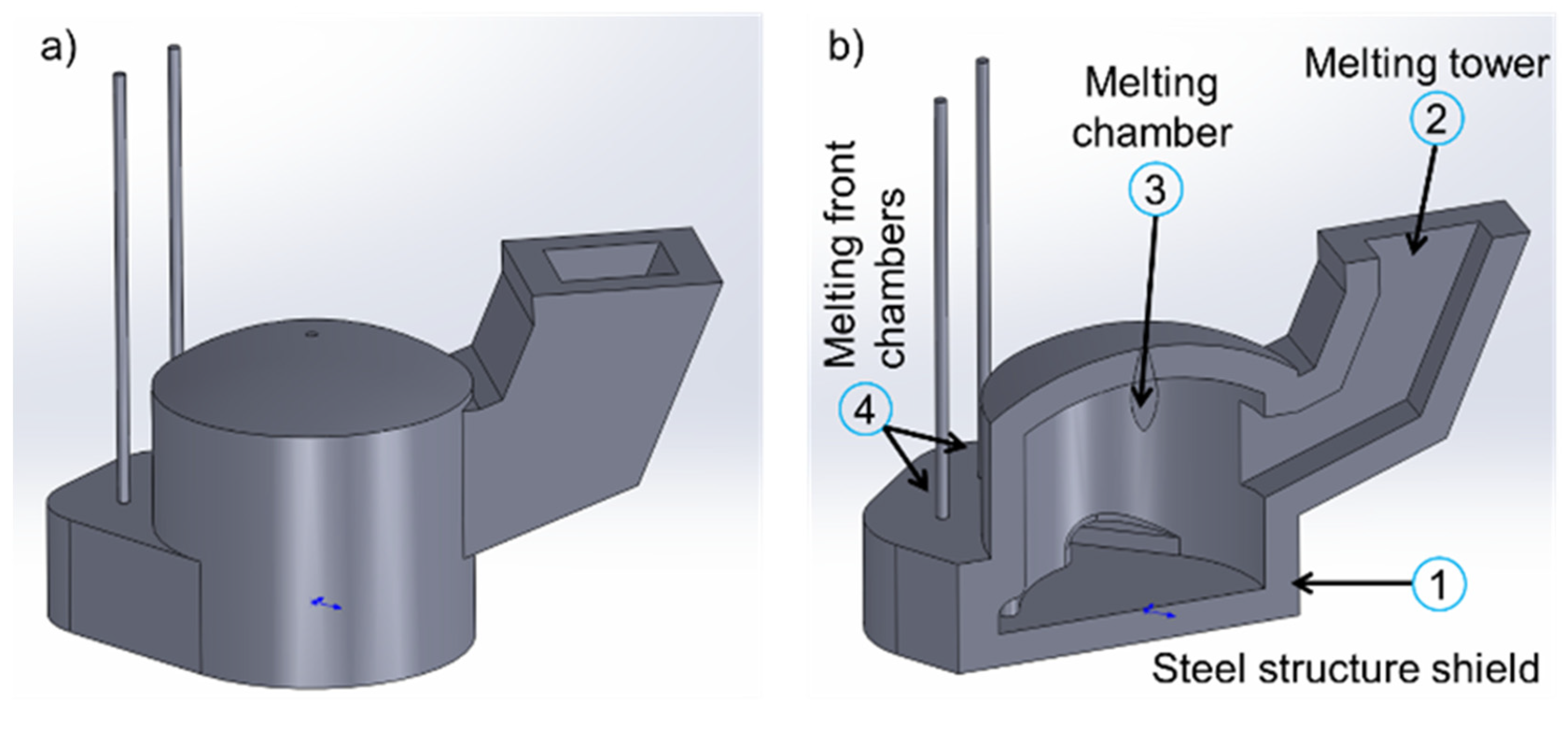

Metals Free Full Text Mathematical Modelling For Furnace Design Refining Molten Aluminum Html

How To Melt Metal In Casting Foundry Melting Furnace Technologies

0 comments

Post a Comment